Home

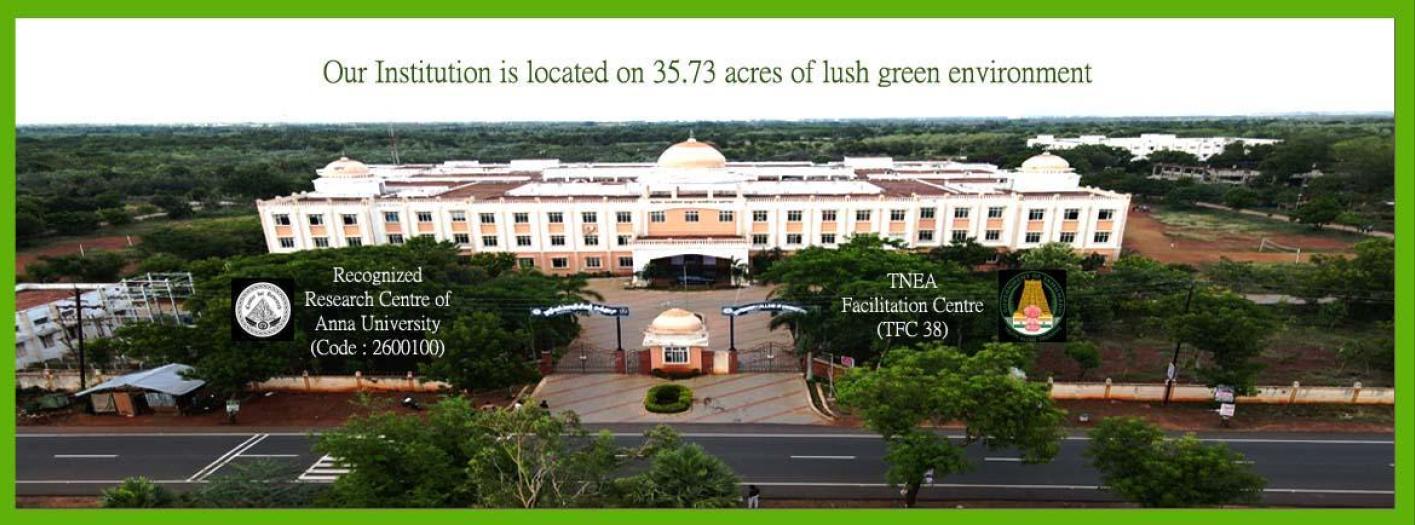

Government College of Engineering, Sengipatti, Thanjavur was started in the year 2013 by Government of Tamilnadu to cater for the needs of technical education in emerging areas of engineering and excellence in research in different disciplines of science and engineering...

Dr. S. Jayabal

“Education is one thing no one can take away from you.” - Elin Nordegren

The beautiful thing about learning is that nobody can take it away from you. The purpose of learning is to gain knowledge and skills that will prepare individuals to lead successful and fulfilling lives. Our high-quality infrastructure, fully furnished laboratories, knowledgeable faculty members, modern library facilities, student-centric activities, digitization of teaching-learning process, innovation...